Constellation Energy, the largest nuclear plant operator in the U.S., has embarked on an ambitious endeavor to construct a full-scope glass panel simulator in support of a significant digital modernization project at the Limerick nuclear station near Philadelphia, Pennsylvania. An upgrade to Westinghouse Ovation digital control system in the plant presents challenges in meeting design and training requirements with the existing single training simulator. Constellation identified the need for a second simulator that could be easily modified to reflect the evolving stages of the modernization project.

The new simulator features high-resolution (4k) 55″ touch screens for bench boards and vertical panels, along with additional displays for annunciators to accommodate changes throughout the digital modernization project. Computers drive all touch screens, networked to a simulator computer running the Limerick simulator load and instructor station. Incorporating Ovation displays and controls supplied by Westinghouse, the simulator offers a comprehensive training and testing environment.

CORYS has been a long-time simulator vendor for the Constellation fleet, and was selected to develop and install the new simulator. CORYS, chosen for their low-risk approach and state-of-the-art technology, spearheaded the project with close collaboration between their engineers and Constellation’s team at Limerick.

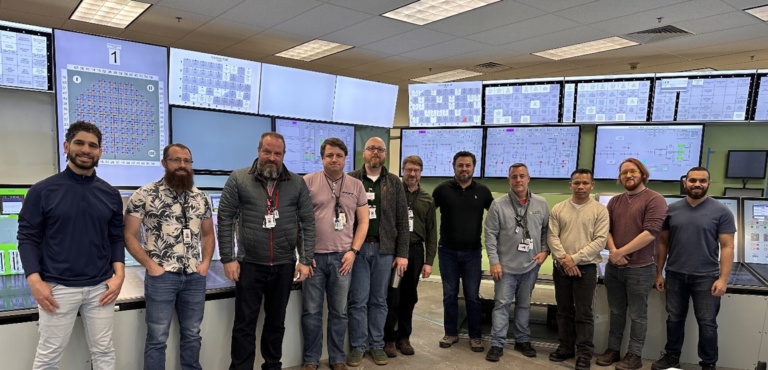

After design and construction of the simulator factory testing focused on device integration, startup/shutdown procedures, and plant operations using panel devices. The existing Constellation panel graphics were maintained and enhanced to 4k resolution. Real-time and repeatability were tests conducted to ensure model execution remained unaffected. CORYS developed FAT test procedures, subject to Constellation’s review and approval. CORYS, assisted by Constellation engineers and instructors, conducted the FAT at CORYS facilities in Jacksonville, Florida in January, 2024.

After a successful factory test program, the simulator was disassembled, packed, and transported to the Limerick site. CORYS personnel oversaw the installation and supported the site acceptance test, remaining on-site until testing could proceed independently. Remote support was provided thereafter, with on-site assistance as needed. The Limerick GPS installation was successfully completed in February 2024, marking a significant milestone in Constellation’s commitment to modernizing operations and enhancing training capabilities.