No, the 6 DOF motion system is not necessarily the best choice for a full-scope train, subway and tramway simulator. 5 DOF is more realistic, less bulky and not necessarily more expensive. Demonstration.

What is the difference between a 5 DOF and a 6 DOF, from the user’s point of view? Not much, just one degree of freedom: the 6 DOF can turn a cab to the right and left. For the rest, both systems have the same possibilities. They move the cab back and forth, left or right, up or down, and tilt it to the side (roll) or back and forth (pitch).

However, this minor difference is the source of real debate. Realism advocates plead for the 6 DOF, which is more comprehensive and therefore supposedly more faithful to driving conditions. Pragmatists believe that a 5 DOF is sufficient and offers other advantages. This is the debate we wanted to shed light on 5 criteria.

Realism : 5 DOF has the advantage

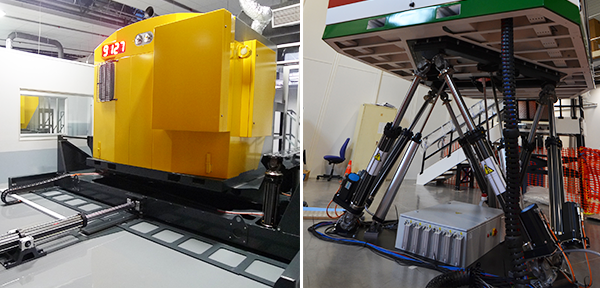

Let’s break a stereotype. The 6 DOF motion system is not the most realistic because of its design. It should be specified that it is made up of a hexapod of 6 cylinders, which are attached to each other: for each movement, they are all put to use.

This configuration is appropriate for movements of low or medium intensity. On the other hand, it reaches its limits on very marked movements, for example emergency braking in a tight curve on a slope. The desired movement of some cylinders is then prevented by other cylinders that have already reached the end of their stroke. An experienced driver will immediately notice the difference with reality.

However, the 5 DOF consists of a tripod placed on a cradle that moves back and forth and left to right. The movements are decoupled, not constrained by mechanics: it is possible to more faithfully represent real driving situations, in particular the sensations of acceleration and braking which are critical for a driver.

Price : 6 DOF has the advantage

Used for aircraft simulators, fun parks, fairs etc., the 6 DOF are mass-produced and available on catalogue.

Conversely, the 5 DOF are only used for railway simulation and are manufactured on demand. Despite their less sophisticated electronics, their mechanics are more complex and they cost almost twice as much. But don’t jump to conclusions: ask yourself where you will install your simulator…

Volume : 5 DOF has the advantage

A 5-axis motion system is about 70 cm high, compared to 1m20 for a 6 DOF system. Above all, it is designed for railway simulation, where the amplitude of motion never exceeds 7 degrees. Whereas a 6 DOF offers +/-45 degrees in all directions: this is essential to reproduce the movements of an aircraft or to offer thrills to ride customers.

Of course, the 6 DOF will be limited to 7 degrees for its “rail simulation” use. But safety regulations require the building to be sized according to its maximum possibilities. A simulator cabin that moves +/-45 in all directions occupies a very large theoretical “spatial envelope”.

Result: where about 4 m below the ceiling suffice for the 5-axis and the cabin , the 6 DOF will easily require 6 m and a “safety perimeter” of almost 2 m around it.

Installation : 5 DOF has the advantage

The constraints of the 6-axis space requirements almost always impose the construction of a large specific building. It must also be equipped with a reinforced concrete slab at least 60 cm thick. This is the minimum required to put in place strong enough anchors, that will withstand the pullout stress of a 2-ton cabin inclined at 45 degrees.

A 5 DOF produces much lower ground stresses and will make do with a standard industrial building.

You must therefore consider the building before making your choice. The 6 DOF, which is much more competitive to start with, could prove to be much more expensive.

Images : 6 DOF has the advantage

Concerning the image, the mass of a 6 DOF motion system and the show of its moving cylinders clearly outweigh the discreet 5-axis template.

If your simulator is to enhance the attractiveness of your training, attract and impress recrutes, don’t hesitate. In railway simulation, as in other professions, technical arguments do not necessarily prevail!