The two companies enter a strategic agreement to advance digital twin modeling and simulation technology across energy and process industries

The agreement reflects a strategic collaboration between ABB and CORYS, with both companies committed to delivering advanced digital twin technology to help drive down capital and operational costs and reduce risks for customers.

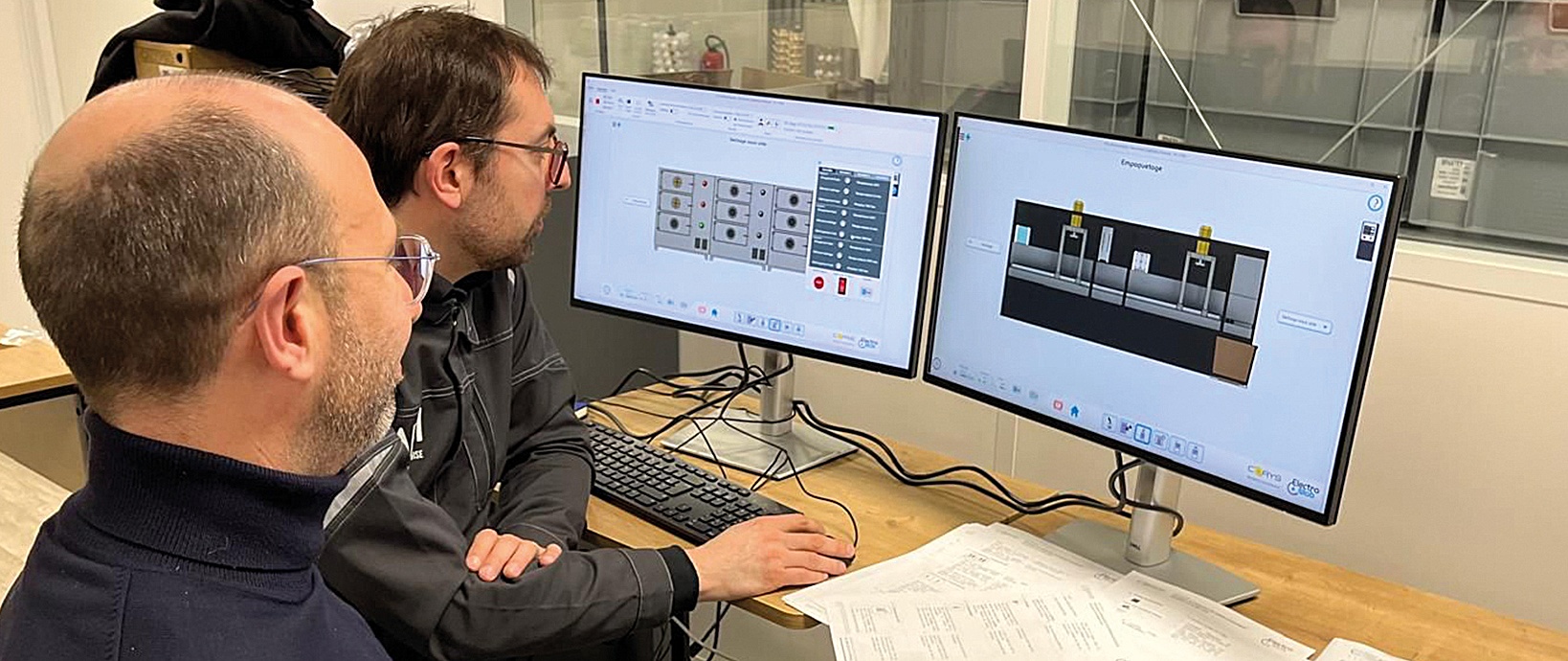

Leveraging ABB Ability™ 800xA Simulator, ABB delivers complete digital replicas of a plant’s control system. Combined with CORYS’ dynamic high-fidelity Indiss Plus® process modeling simulator, customers will benefit from a complete digital twin solution, that supports training and allows operators to validate and test control strategies and production processes, as well as manage changes during the lifecycle of operations.

Charles Rosmorduc, CEO of CORYS, said:

“We are proud to enter into this strategic partnership to develop and integrate CORYS’ products with ABB allowing our mutual clients to improve safety and operational efficiency.”

The collective digital solution is expected to reduce capital expenditure in greenfield projects, by improving quality of the control applications, reducing number of late changes, training the operators and by reducing the number of commissioning and start up hours.

Colin Ward, Chemicals and Refining SVP for ABB Energy Industries said:

“In today’s economy, our oil, gas and chemical customers are exploring all ways to maximize return on investment in operations. Digital twin modeling and simulation creates more confidence in executing projects – reducing cost, schedule and risk – and helps operators identify and understand improvement opportunities across an asset’s complete lifecycle.”

Also applicable for use in brownfield sites, operators can utilize the ABB-CORYS digital twin package to build intelligent models and run scenarios to increase performance of plant operations. This includes improving plant efficiency and availability, as well as reviewing and managing equipment and assets across the plant, enabling maintenance teams to build an effective condition-based maintenance programme.

This global framework formalizes a successful business relationship between the two companies.