PROCESS SIMULATION

A Worldwide Leader

in Simulation

CORYS is a global leader in real time high-fidelity dynamic process simulation, engineering, and training for process industries.

Our products and services provide world-class experiences that set new standards in operator training by teaching energy efficiency, reliability and safety.

Headquartered in Grenoble, France, we have delivered simulators in more than 60 countries.

We support a worldwide fleet of more than 2600 simulators.

Industries

CORYS serves all process industries, ranging from upstream offshore platforms to downstream refining, chemicals, and polymers. We also support new biofuels technology, as well as renewable energies, and midstream companies.

Solutions

CORYS’ core solution is dynamic process simulation that accurately simulates your process across a wide range of conditions including start up, shut down, and steady state operations. We also provide engineering and training solutions to support the use of simulation in your organization.

Products

With products ranging from our Companion Training Manual to 3D immersive simulation, we have the ability to meet our customers’ training and simulation needs and help them ensure safe and efficient operations.

An Global Footprint

dynamic models delivered to Process industries

countries

The CORYS Advantage

Lower TCO

High fidelity simulators recognized by the industry and flexible solutions designed to last

On-time delivery

Our OTD rate is 99% and we are experienced in building during rolling stock production

Responsive service

Local project managers and support experts onsite worldwide

Partnership

Committed to ensuring customer satisfaction and meeting our customer’s needs

Innovation

Commitment to investment in research to ensure we are delivering the latest in simulation technology

Community

What our customers are saying

- INDISS PLUS is using one single light simulation server easily while other requires heavy servers for the same scope.

- INDISS PLUS is very robust and server has not face speed problem issues after installation at site.

- INDISS PLUS includes an efficient and very user friendly instructor platform with Automatic Training Exercise and Trainee Performance Monitoring.

Process Industries News Updates

Renewable Fuels Pretreatment Training Simulator for PREEM

PREEM AB has chosen CORYS to deliver a high-fidelity Operator Training Simulator (OTS) for its new HydroThermal Cleanup Unit (HCU),...

Renewable Fuels Pretreatment Training Simulator for PREEM

PREEM AB has chosen CORYS to deliver a high-fidelity Operator Training Simulator (OTS) for its new HydroThermal Cleanup Unit (HCU),...

CORYS and Hydrogen Africa Partner to Enhance Hydrogen Training through Simulation

On August 1st, 2025, CORYS and Hydrogen Africa formalized a strategic partnership through the signing of a Memorandum of Understanding...

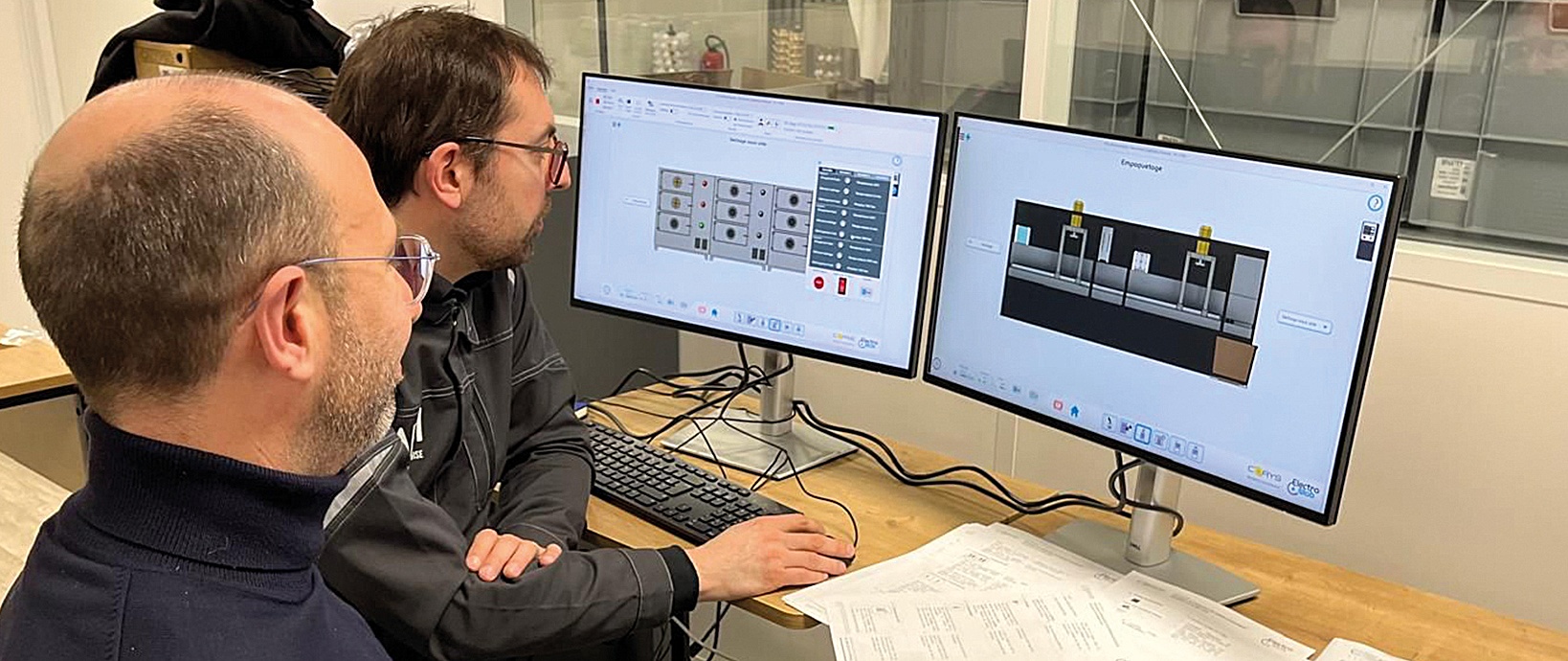

Simulation is Irreplaceable for Training on New Processes

Nicolas BallandElectro’Mob Project Director, ARIA Training thousands of operators,technicians, and engineers in the production of battery cells for electric vehicles:...