Nicolas Balland

Electro’Mob Project Director, ARIA

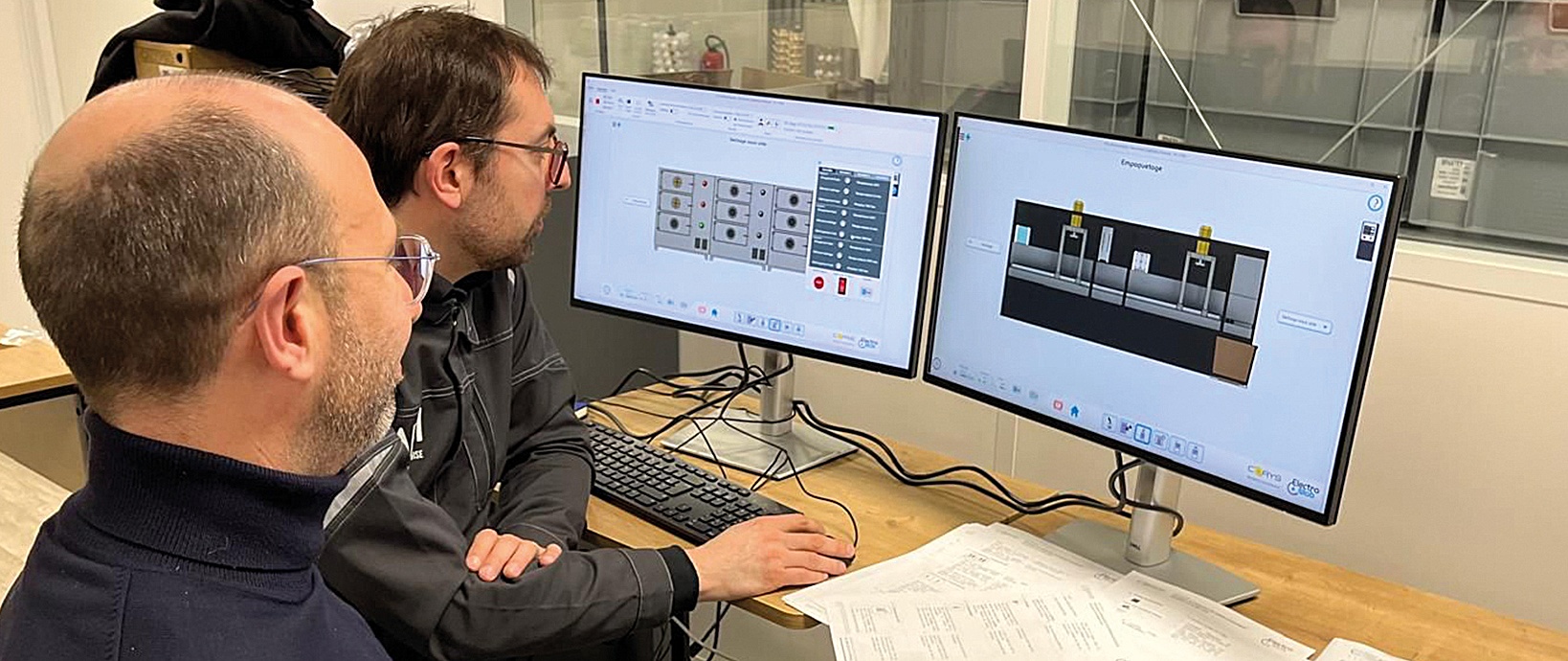

Training thousands of operators,technicians, and engineers in the production of battery cells for electric vehicles: this is the purpose of the simulator delivered by CORYS to Electro’Mob, the consortium developing a sustainable electromobility sector in the Hauts-de-France region.

For project director Nicolas Balland, this new tool will play a decisive role.

Can you briefly introduce Electro’Mob?

Electro’Mob is a consortium of around forty partners, including automotive manufacturers, battery industry players, academic and university stakeholders, all working together to build a complete value chain for the production of electric and hybrid vehicles in the Hauts-de-France region. The most visible element is the gigafactories that are under construction or about to start up. To operate them, we will need to train 13,000 employees — from operators to engineers — in processes that are entirely new to everyone.

What role does the CORYS simulator play in your training program?

It provides us with a digital, interactive version of the production lines — the heart of a battery cell plant — something no training organization can offer at full scale. It allows future employees to train on the process before starting on the job. It is a vital addition to the regional education system and to our four technical platforms, where we reproduce the physical environment of a gigafactory.

What does the simulator include?

It models the various workshops in a production site, including operator actions, maintenance tasks, quality controls, and key failures and defects. It is the ideal tool to develop practical understanding, build intuition and reflexes, master best practices and diagnostic methods, and react appropriately to serious incidents, such as a foil breakage in an oven. CORYS provides a dozen training scenarios, and instructors will be able to create new ones as needed.

Do battery manufacturers find the simulator realistic?

We aim for realism and accuracy, but the goal is not to create a digital twin of an existing site — that’s not necessary given the diversity of the people we need to train. The validation we conducted at the beginning of 2025 based on these specifications was fully convincing, especially from the perspective of industrial partners.

Can the simulator evolve?

This has been planned from the start, and it’s essential for a process that everyone is discovering as they go. Battery manufacturers already operating production lines will share their feedback, which can inspire new scenarios. Additionally, version 1 of the simulator currently covers only prismatic cells, but version 2, expected at the end of 2025, will also cover high-energy-density pouch cells.

If you had to do it again, what would you change?

The simulator would have been even better if we had made more pedagogical efforts. Some stakeholders thought it would be self-sufficient or even replace trainers. As a result, they were less involved in its development or submitted suggestions too late to be incorporated. Yet simulation is irreplaceable when training on new processes; once you have it, you need to take full advantage of it.

Project supported by the French State under the “Compétences et Métiers d’Avenir” call for projects within the France 2030 program, operated by Caisse des Dépôts.

Co-financed by the Hauts-de-France Region